Partner - How is an ERP implemented? All you need to know about ERP implementations.

A successful ERP implementation is a result of choosing the right people and approach. Let's talk about what makes it successful.

·

9 min read

ERP implementations are time consuming and expensive. Before committing to one, you should be aware of the landscape. The method, software, business fit, everything matters. Regardless of whether you’re new to the ERP market or considering a change, this post will help you identify and navigate common ERP implementation problems.

In this post, we’ll talk about different ERP implementation methodologies used, what factors to consider, the challenges, best practices, and even common reasons why ERP implementations fail.

Let’s get started.

ERP implementation life cycle

To give you some background, first, let’s take a look at a typical ERP implementation life cycle. You can call these the steps occurring in an ERP implementation.

1. Evaluating ERPs

You’ve decided to get an ERP for your company or replace the current one you’re using. So you search the internet, visit review sites, and even ask others in your business circles. Vetting ERPs thoroughly is very important to see if it’s a good fit for your company in terms of features, usability, cost, etc. You’ll get deeper information only with a demo and consultation. Understand the ERP system to get an idea if it’ll work for you. You should research plenty and get a lot of information. Discuss with senior leadership as to what’s important for your company before choosing an ERP.

Tip: An ERP is like marriage, a long term commitment, and breaking it off midway will cost you dearly.

2. Gap analysis

Done by the consultants of your ERP service provider after understanding your current system. Consultants identify the gaps between the ERP and your current business processes. For example, you may be manufacturing artificial diamonds and the ERP software currently doesn’t have all features to map it.

Tip: Consultants can identify gaps only when you explain your business thoroughly.

3. Data migration

Once it’s clear that your business processes can be mapped into the ERP, data migration begins. This means importing all your existing data from the old system to the new ERP. Financial records, transactions, customer, supplier records, importing all relevant business data minimizes some level of disruption.

Tip: Always keep your data ready to import before the implementation.

4. Customization

This brings us to customization. This involves filling in gaps with custom developing features. Customization takes care of all the gaps so that your business can fully map all processes to the expensive ERP you’re implementing.

Tip: The general rule of thumb is to keep customization at a minimum. It’s easier upgrading to new versions this way.

5. Testing

Before calling the system production ready, multiple rounds of testing are a must. This is especially true when a lot of customizations are involved. Both the ERP service providers and the client company tests the system to filter any bugs so that it runs smoothly in production.

Tip: Take feedback from employees to identify any bugs or roadblocks.

6. Go live

When all gaps are filled, employees have adapted to the new ERP, and extensive testing is done, it’s time for your ERP service provider to declare that the implementation has been completed. This brings you to AMC or support arrangements where the ERP service provider charges an annual fee to maintain the software and provide assistance. It’s a good idea to measure changes pre and post ERP implementation to see how much time you’re saving.

Tip: Ensure your organization is happy with the settings and customizations before the implementation ends officially.

ERP implementation methodologies

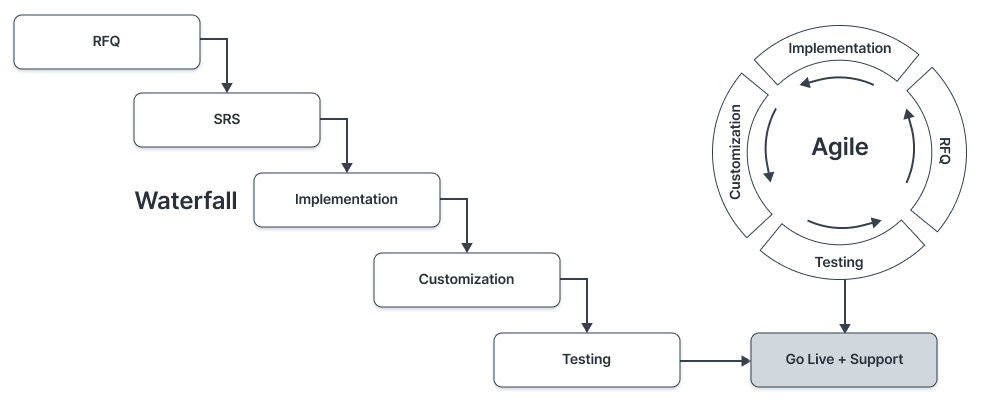

Before starting any ERP implementation, choosing the correct method and setting expectations with the provider is crucial. Broadly, there are two methods used—Waterfall and Agile. Let’s see the difference.

Waterfall

In the Waterfall method, all the points you see above are followed one after the other. The process doesn’t move ahead until the previous step is complete. That means you can’t even start the ERP implementation if the specifications/requirements documents aren’t addressed fully.

While it may sound organized, the Waterfall method actually causes a lot of ERP implementations to fail. Why you may ask. Well simply because it’s time-consuming and people lose patience. This is an older model popular even today in large companies.

Agile

In Agile, all the points are still followed one after another. The difference is that the next step can begin while the previous step is still in progress. Agile allows multiple steps to run in parallel and also revisiting steps for iterations and improvement. For example, you can go live with Purchase and Stock modules while modules like Manufacturing and sales are under user testing. This allows you to do incremental changes which smoothens the change management challenges for the company.

While in Waterfall, the resources are predetermined, in Agile, they’re added on the go. This is a nicer approach since you cannot make perfect calculations on how much resources the implementation requires. Since processes run parallelly, communication is key when using the Agile method.

Here’s a diagram to draw comparison:

What’s business process mapping in ERP?

Before starting with an ERP implementation, it’s important to know your company’s current business model and operational challenges. An ERP service provider’s consultants will give you a demo and discuss your business processes. Usually, a deeper discussion leading to implementation is done after you subscribe to an ERP service.

For business process mapping, your business use cases and scenarios are mapped to the ERP software of your choice by consultants. This can take a couple of days or several weeks depending on the complexity and scale of your business. Once it’s clear that your business can be mapped into ERP software, you can say that the ERP is a fit for your business and the process enters the implementation phase.

ERP implementation challenges

To get your ERP implementation running smoothly, you should be aware of the common challenges that occur during the implementation phase. These are common pitfalls:

1. Project champion ambiguity

A project champion is a single point of contact between the ERP service provider and the company. Ideally, they should be a senior employee who is well versed in the business processes of your company. In smaller companies, it’s the owner/accountant and in larger ones, they are from senior management. Ambiguity on who is the project champion or having multiple project champions causes miscommunication and chaos. The project champion should be a focused and driven individual.

2. Failing to drive change management

The project champion along with senior management is expected to prepare and drive the employees towards the new ERP. Motivating people to change is not easy. Often, changes in business software are met with resistance. Only if the employees accept the new ERP the company can successfully use the ERP software. This also includes training the staff to use new ERP.

3. No involvement from Senior Management

Implementing an ERP is an organization-wide big change, hence senior management participation is crucial. If the senior management, (VPs, directors, etc.) aren’t there to support, drive change, and resolve conflicts, the implementation process runs without internal expert guidance.

4. Underestimating costs

Depending on the complexity, diversity, employee strength, and other factors of your business, the total costs of an ERP implementation can vary a lot. As a general rule, the costs increase with business complexity and diversity. In simpler words, more complex and different activities result in higher implementation costs. Hence, it’s important to be upfront with your service providers and share all relevant information to predict the costs as accurately as possible. Keep in mind that unpredicted on the fly extra software developments add more costs.

5. Business edge cases

Many businesses will have some niche processes that require additional development or customization in the ERP. But if your business has a lot of such niche processes, it’ll delay the implementation to some extent and may also end up costing you more.

Common reasons for ERP implementation failure

Choosing and getting an ERP up for business use is expensive in both time and money. So it’s favorable to avoid all mistakes and stay on safe shores. The losses from failed implementations are so serious that many companies have even gone bankrupt trying to implement ERPs. Implementation failures in ERPs happen due to reasons ranging from choosing the wrong implementation strategy to a lack of employee motivation. Let’s take a look at them:

1. Implementation methodology

As we already discussed in a previous section, the choice of implementation method greatly affects the speed of implementation. In mature businesses, where the business process is complex, taking the Waterfall approach can be disastrous enough to make the whole project slip. Frappe has observed such cases quite often.

2. Miscommunication of goals

Initially, you talk to the ERP consultants about your business goals and requirements. 2 months later, you realize that you forgot to mention a couple of important things. This is a recipe for disaster. If you forgot to mention something as crucial as the interdependency and relations between business units, it changes large part of the ERP implementation. Such a situation will delay the implementation and in the worst-case steer towards failure. This also requires you to be thorough with requirement gathering.

3. Resource scarcity

After finding the fit and goals, say you enter the implementation. A month later you realize that there aren’t enough people in operations to help with the implementation tasks or the accounting department doesn’t want to participate in the new implementation. There you go, more delays and even halts. Well, accountants are creatures of habit getting accustomed to any software they’re using.

4. Being hung up on customizations

Customizations are inevitable since every business is unique and has it’s own requirements. But it’s important to determine when to proceed with them and when to stop. Trying to fill every small business gap with more customizations will only make the process draw out longer. This results in the go-live date to be pushed further and further.

5. Data migration friction

Now, consider that you’ve begun your ERP implementation and the data is not ready. Worse, even if the data is ready, it’s messy with problems like data duplication and incorrect records. Guess what? Your implementation gets delayed again. And this one really hurts since it can take anywhere from weeks to months getting the data ready for migration. This is such a crucial step yet so many companies seem to ignore it.

ERP implementation best practices

Learning from the challenges and reasons for failure, now let’s see a list of some best practices. This is not a foolproof plan, mistakes happen, but these points will save you a lot of pain.

1. Keep your data ready

Your current company data is key. Hence, it should be a mandatory practice to keep your data clean and ready. The biggest reason to keep data ready preemptively is so that no time is wasted when the actual implementation begins. Yawn, I know, it’s boring but has a high impact on speeding up the ERP to production-ready phase.

Many times companies dive into ERP implementation and their company data is far from ready. In rarer cases, the companies also blame the ERP provider ironically, for delayed implementation.

2. Be clear about your goals, communicate

Have a clear understanding of your whole business process and gather all the requirements. These requirements will be mapped to the ERP you’ll be using. Needless to say, be thorough with your research and understanding. Do not leave any requirements or expected goals to be achieved from the ERP behind.

3. Make sure everybody is aboard

From the CxOs to new joiners, every employee who will be using the ERP has to be on board. This means different things for different roles. CxOs, VPs, and directors are expected to support change and solve complex problems or challenges that arise during implementation. The most common one is resistance to change. Individual employees or groups need motivation and training to use the new ERP.

4. Thorough UAT

Yet another indispensable part is thorough user acceptance testing. Ensure that the ERP you’re implementing fulfills all the requirements across departments and also between departments. The transactions, reports, integrations, etc., everything should be running smoothly before accepting the system for production.

5. Use first, customize later

As we’ve already discussed, customization is important. But you know what’s more important? Ensuring that the critical processes are up and running first. Anything that does not stall business can wait. These smaller features not critical to daily business are known as secondary customizations.

Who will implement my ERP?

In most cases, there are ERP implementation consultants that figure out business process fit and proceed with implementation. Many ERP providers have a network of partners that carry out the implementation. Unorthodoxically, we think that your internal company employees are the best people to drive an implementation faster with some consulting but we likely dissent.

Conclusion

If you avoid the common mistakes, follow some best practices, and make the right choices a successful ERP implementation is underway. As we saw, an ERP implementation is a long term project requiring significant commitment, time, and money. Implementing an ERP is only half the picture, you also have to use it well to get the best returns out of it. Consider an ERP implementation like buying a treadmill. To make things work, you also have to run on it regularly.

ERP implementations don’t have to be expensive, all it takes is a bit of dedication and commitment. And who else would be more responsible for your company’s ERP implementation than one of your own employees! If we’re talking about ERPNext, you can implement it all by yourself with some guidance from the team at Frappe.

No comments yet. Login to start a new discussion Start a new discussion